A high flux, small diameter heating rod capable of producing 2.5MW/m2 in a matter of tens of milliseconds

Background

With the renewed emphasis on the development of advanced reactor technologies, there is an interest in assessing the performance of materials under both normal operating conditions and during hypothesized incident scenarios. Use of nuclear test facilities can be prohibitively expensive and difficult to schedule. The ability to stress materials in a dynamic facility, with operating conditions similar to those of a nuclear reactor, without radiological concerns, is of great benefit to the entire nuclear community. Vendors who can produce necessarily small-sized (by diameter) cartridge heaters for this testing purpose struggle to provide power densities above 15 W/cm2 at a small form factor. There is, therefore, a need within the nuclear fuels community for a tool that can produce appropriate power densities representative of an actual rod in an active fuel assembly.

Technology Description

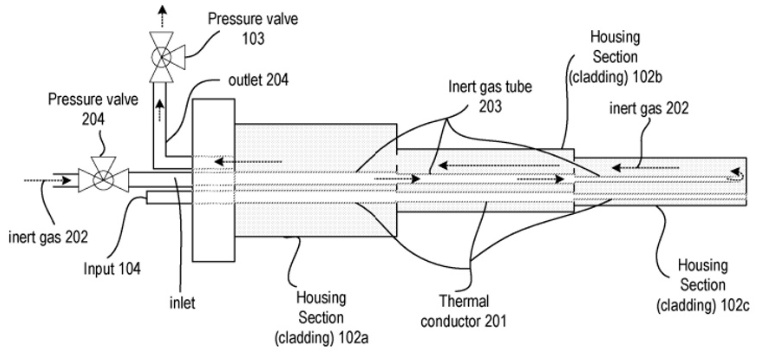

This technology provides for improved simulation of nuclear reactor fuel rod pulsation for research and testing purposes. The device is a resistive heating filament capable of producing 2.5 MW/m2 of energy in a matter of tens of milliseconds with an outer diameter of less than a centimeter (0.9525 cm). This responsive heating element has a minimal internal ceramic support structure which allows for rapid changes in thermal flux at the surface of the heating element.

Features & Benefits

- Small diameter size (<1cm)

- Rapid thermal energy creation (2.5 MW/m2)

- Rapid response (fraction of a second)

Applications

- Reactor testing and simulation

- Where rapid changes in thermal flux are required

Opportunity

Seeking commercialization partner.

Status

Patent application submitted US20200402678A1