Background

Hybrid compact heat exchangers are being considered as secondary heat exchangers for supercritical carbon dioxide (sCO2) power plants. Architecture for efficient heat exchangers require thin sidewalls between the sCO2 channels and other fluid (e.g., molten salt). Generally, a stiff, corrosion‐resistant material capable of high temperature will be required. High chromium iron‐based ferritic oxide dispersion strengthened (ODS) steels are promising candidate materials for these applications. However, they are not readily available commercially or widely utilized because of their high production costs and difficulties in manufacturing, machining, etc. This technology provides a method and composition for making ODS steel via additive manufacturing.

Technology Overview

Researchers at OSU have developed a method for producing ODS steel using additive manufacturing techniques. Compared to conventional means for making ODS steel, this process avoids challenges with casting, ball milling, and component fabrication by selective doping of the oxide phase into a powder bed prior to fusion and being manufactured into a component. The material can be directly incorporated into components, cutting out many conventional forming steps with the potential for significantly reduced development time and manufacturing cost to produce a net shape component. The quality of the resulting ODS steel is comparable or better than similar materials made by conventional methods.

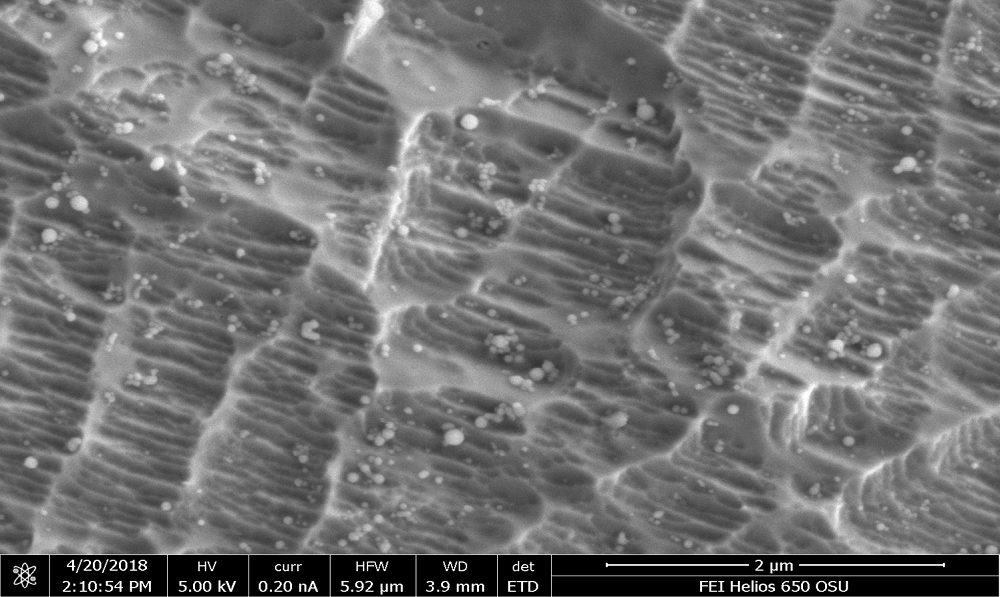

Figure 1: SEM image of ODS steel sample

Benefits

- Cheaper manufacturing

- Additive manufacturing build control

- Control over composition

Applications

Components for:

- Supercritical power cycles

- Sodium fast reactors

- Extreme environments where conventional steel fails

Opportunity

Seeking development and licensing partners.

Patents

IP Status

- Provisional patent

- Patent application submitted

Seeking

- Development partner

- Commercial partner

- Licensing