New production method to create amorphous alloys that possess superior mechanical properties compared to crystalline metals

Background

Conventional metals or alloys comprise numerous crystal grains and crystal-related defects such as grain boundaries, dislocations and vacancies/voids. Amorphous alloys, also known as metallic glasses, are free of crystal grains and crystal-related defects, and because of this, possess many properties far superior to conventional alloys. Examples of such properties are theoretical-limit approaching strength, high hardness, high elastic strain limit, and high wear and corrosion resistances. Although a large number of bulk metallic glasses have been developed since 1990s, only a handful of them have passed the mark of 15 mm in the critical casting thickness. This not only limits the material choices for fabricating large metallic glass articles with all dimensions >15 mm, but also demands stringent control (in terms of, e.g., oxygen-free environment, impurity level) over fabrication conditions for moderate-sized articles. There is a clear need to develop new metallic glass compositions with the critical casting thickness above 15 mm.

Technology Description

This invention describes bulk-solidifying amorphous alloy compositions based on a Cu-Zr-Hf-Al quaternary system with the addition of a small amount of additional alloying elements. The technology further describes methods of casting the alloy compositions in a manner that maintains amorphous structure in three dimensions larger than currently available in the art. Bulk metallic glasses such as this composition possess superior mechanical properties compared to crystalline metals and yet have much lower requirements on the cooling rate that enable fabrication of more practical-sized commercial articles.

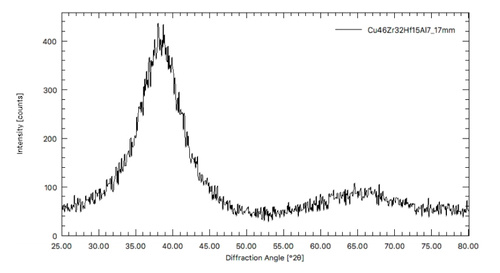

X-ray diffraction of an alloy sample 17mm in diameter

Features & Benefits

- Ability to make larger particles

- Reduced fabrication costs

- High glass-forming ability

Applications

- High-strength components

- Corrosion resistance

- High-precision parts

Opportunity

Seeking development partners

Status

Patented: US 11,821,064 B2